Product Code: PP217B

This machine is applicable for packing powder, granule, liquid in form of top spout flat pouch or top spout stand up pouch, with different patterns of sealing, which include processes of flat pouch or stand up pouch forming, product dosing, filling, top spout installation and sealing.

This machine is applicable for packing powder, granule, liquid in form of top spout flat pouch or top spout stand up pouch, with different patterns of sealing, which include processes of flat pouch or stand up pouch forming, product dosing, filling, top spout installation and sealing.

| Issue | Application Description |

| Applicable Pouch | Top spout flat pouches, top spout stand up pouches, or other irregular top spout pouches. |

| Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder or granule, such as juice, honey, soybean milk, jam, ketchup, mayonnaise, baby puree etc. |

| Applicable Packaging Material | Laminate Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL /CPP etc. |

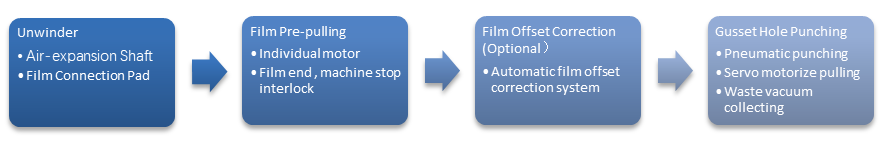

Film Unwinding Process

Note: the gusset hole punching process applies for stand-up pouch

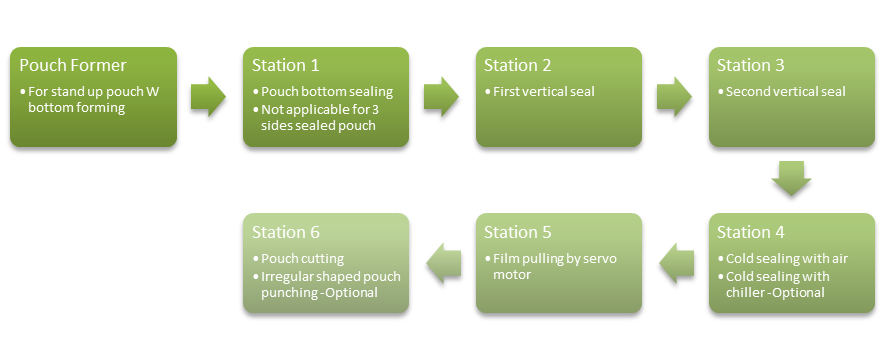

Pouch Forming Process

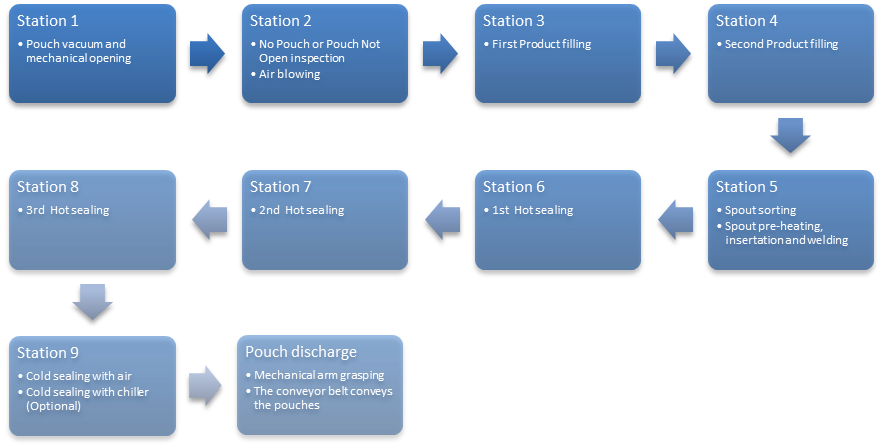

Pouch Filling Sealing Process

Note:

1)The product filling process can be 1 station according to project requirement

Standard Features

1)Stand up pouch form fill, top spout installation and seal

2)Rigid carbon steel structure with plastic spraying process and covered by stainless steel 304

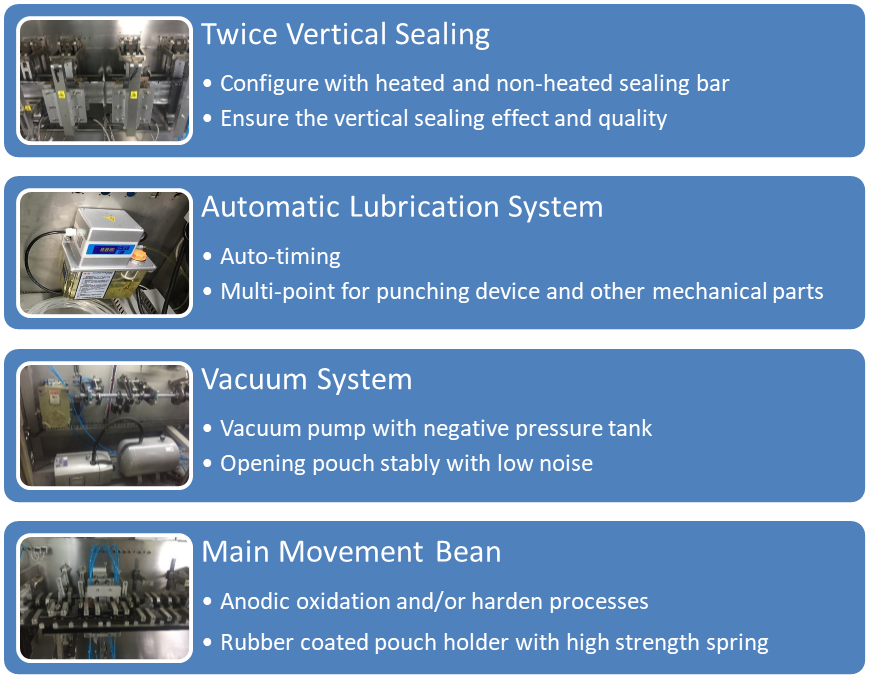

3)Anodic oxidation and/or harden aluminum for main movement beam and pouch holding bars

4)Stainless steel 304 for product touching parts

5)PLC & Touch Screen HMI Control

6)Intelligent PID temperature controller

7)Servo motor for film pre-pulling and bottom hole punching

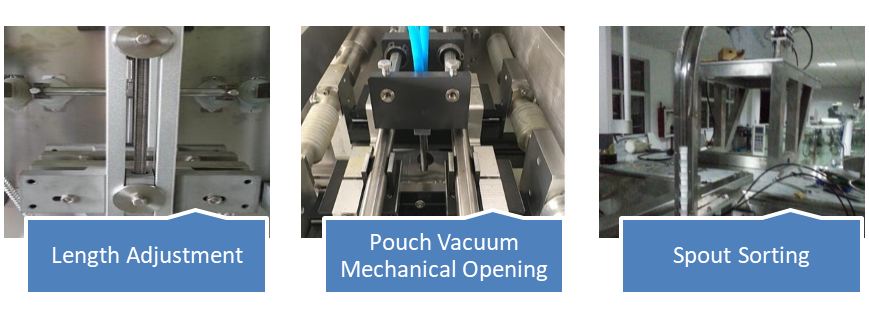

8)Easy pouch length adjustment

9)Twice product filling, twice vertical sealing processes

10)Once pre-heating, three times pressurized heat sealing, once cold sealing, used for top spout installing and sealing

11)Pouch vacuum and mechanical opening

12)Vacuum system powered by vacuum pump with negative pressure tank

13)Individual pressure tank for different compress air supplies

14)Pouch not open completely, no fill and seal interlock

15)Central lubrication system for punching device and other key mechanical parts

16)Visual Protective Cover

17)Cold Embossing type coding

Optional Features

1)Flat top spout pouch

2)Irregular shaped top spout pouch

3)Stainless steel 316 for product touching parts

4)Automatic film offset correction system

5)Ribbon, inkjet or laser coding

6)Cold sealing with chiller

7)AB Control System

| Type 1G-xxxx | HMK-1600C | HMK-2000C | HMK-3000C |

| Packaging Speed | 35-50 pouches/min | 35-50 pouches/min | 35-50 pouches/min |

| Lanes | 1 Pouch/cycle | 1 Pouch/cycle | 1 Pouch/cycle |

| Vertical Sealing Station | 2 | 2 | 2 |

| Pouch Size-Length | 80-270mm | 100-320mm | 100-400mm |

Pouch Size-Width | 60-180mm | 80-210mm | 80-320mm |

| Film Pulling Driven | Servo Motor | Servo Motor | Servo Motor |

| Power Consumption | 10kw | 11KW | 12KW |

| Power Requirement | AC 380V 50/60HZ | AC 380V 50/60HZ | AC 380V 50/60HZ |

| Type 1G-xxxx | HMK-1600DC | HMK-2000DC | HMK-3000DC |

| Packaging Speed | 60-80 pouches/min | 60-80 pouches/min | 60-80 pouches/min |

| Lanes | 2 Pouch/cycle | 2 Pouch/cycle | 2 Pouch/cycle |

| Vertical Sealing Station | 2 | 2 | 2 |

| Pouch Size-Length | 80-135mm | 100-160mm | 100-200mm |

Pouch Size-Width | 60-90mm | 80-105mm | 80-160mm |

| Film Pulling Driven | Servo Motor | Servo Motor | Servo Motor |

| Power Consumption | 13kw | 14KW | 16KW |

| Power Requirement | AC 380V 50/60HZ | AC 380V 50/60HZ | AC 380V 50/60HZ |

Following is the related video links on our Youtube site

Horizontal Top Spout Pouch Form Fill Seal Machine Series

If need more support , please contact us at : cs@gloex.com.cn