Product Code: PP310

It is applicable for the erect RSC, HSC cases. Include the carton open, bottom folding, bottom sealing processes.

Hot melt glue system is optional. Integrated with case sealer, case packer, weighting system, labeling machine, printing, strapping machine and conveyor system as a production line.

It is applicable for the erect RSC, HSC cases. Include the carton open, bottom folding, bottom sealing processes.

Hot melt glue system is optional. Integrated with case sealer, case packer, weighting system, labeling machine, printing, strapping machine and conveyor system as a production line.

Standard Features

1) Heavy duty mild steel power coated main frame

2) Stainless steel 304 or galvanized rollers for main case touching parts

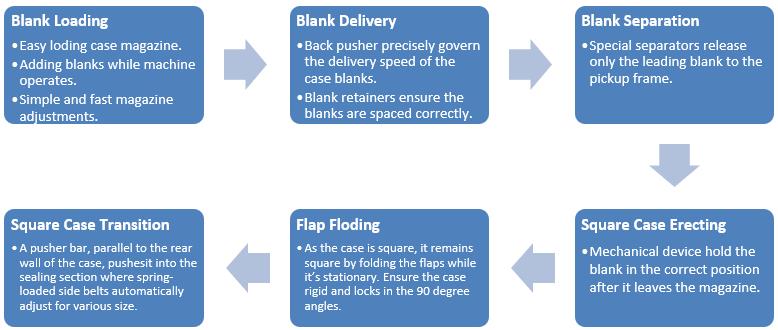

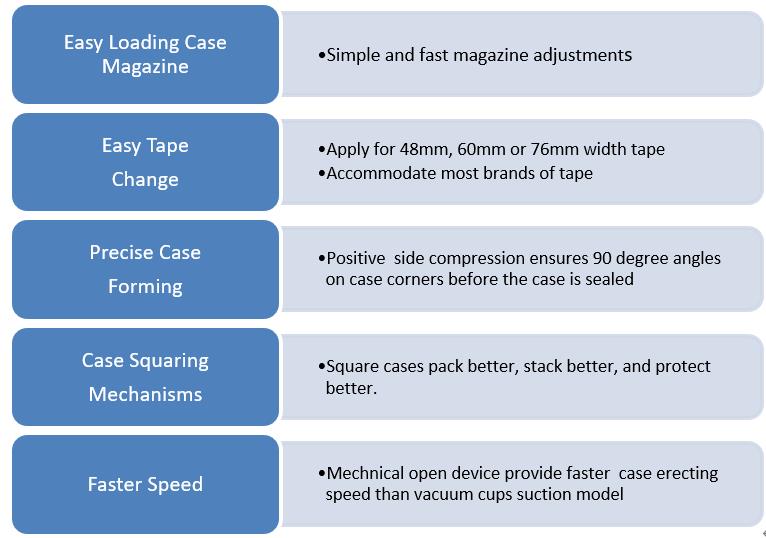

3) Vertical blank loading

4) Case erecting vertically by mechanical device

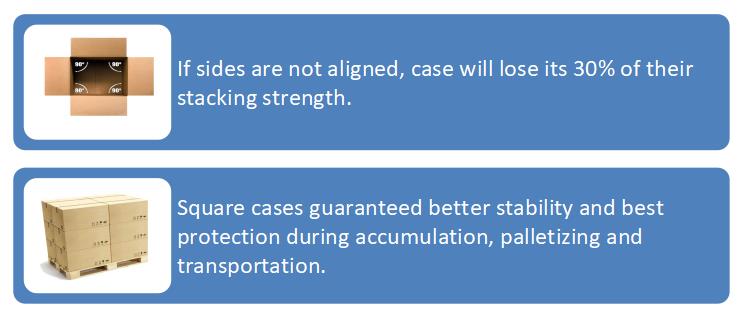

5) 90-degree angle mechanical mechanism enable case Squaring

6) Side belt governed the case transition and bottom sealing

7) Standard tape head sealing configuration

8) Tool less quick case format changeover

9) PLC and Touch Screen control

10) No blank machine stop interlock

11) RSC, or HSC case application

Tips: Square Cases Work Better

Optional Features

1) Glue closure station

2) Stainless steel 304 frame

3) Short side left or short side right

4) Over range size customization

5) Outfeed conveyor

6) All flaps meet cases as option

7) Blade guards, avoid accidental stabbings during operation

Tips : Why use hot melt?

| Hot melt | Tape | |

| Cost | More cost-effect than tape | - |

| Speed | Faster than tape model | - |

| Stability | With flat bottom, more stable on conveyor and pallet

| V-shaped bottom, less stable than flat bottom

|

Practically, the advantages as indicated as following:

| Type | BTK-4540 |

| Motion | Intermittent |

| Speed | 0-19 cases/minute |

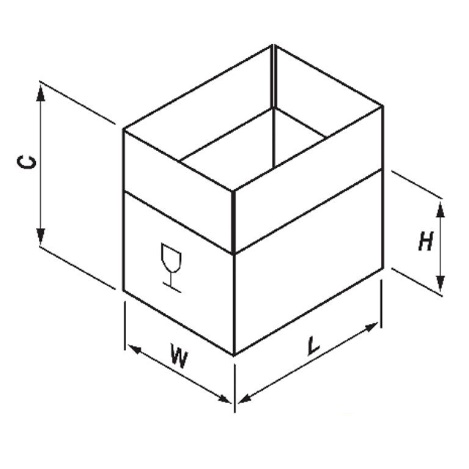

| Case Size Range-L*W*H | (250-450) ×(190-400) × (110-350) mm |

| Tape Head | 60 mm as the standard, 48,76 mm as the option |

| Power Supply | 380VAC 3P+N+E 50Hz 180W |

| Height Of Working Platform | 600mm |

| Air Supply | 6kg/cm² |

| Gas Source Control | 24VDC |

| Dimension-L*W*H | 3020×1250×2000mm |

Following is the related video link on our YouTube site.

Inline Bottom Sealed Mechanical Open Case Erector

If need more support, please contact us at: cs@gloex.com.cn