Product code PP119

This machine is applicable for forming filling and sealing with granule or irregular solidity in form of pillow/flat pouch or side gusset pouch, with different patterns of sealing, and different styles of cutting, which include processes of weighing, film-pulling, filling, pouch-making, sealing and cutting off

This machine is applicable for forming filling and sealing with granule or irregular solidity in form of pillow/flat pouch or side gusset pouch, with different patterns of sealing, and different styles of cutting, which include processes of weighing, film-pulling, filling, pouch-making, sealing and cutting off, the detail application description as following table:

| Issue | Application Description |

| Applicable Pouches | One of the following scenarios can be selected for one machine: 1) Pillow / Flat Pouch 2) Side Gusset Pouch |

| Applicable Products | Capable to pack granule or other irregular solidity such as: 1)Candy, cereal popped food, roasted seeds, nuts and other snacks 2)Crispy, Potato chips, plantain chips, cassava chips, and other various chips 3)Paste, beans, rice and other natural and organic food 4)PET food and treats 5)Individual Quick Frozen (IQF) etc. |

Applicable Packaging Material | Laminate Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL etc. |

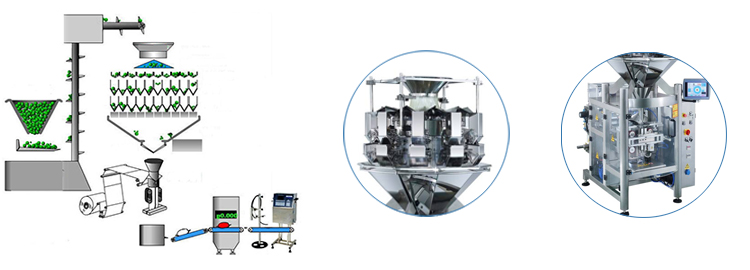

The working processes include: The machine pull laminate packaging film to the pouch forming devices, and go through the vertical sealing plate, in the meanwhile, the dosing device dose the product into the pouch, then will do the horizontal sealing and cutting off. Following are the typical working process diagram:

Standard Features

Flat back sealed pouch form fill seal

Stainless steel 304 construction

Weighing and Packaging Control Integrated

Intermittent motion

Servo motorized film pulling

Pneumatic horizontal sealing and pouch cutting off

Quick, tool less pouch changing over

Intelligent PID temperature controller

Film pre-pulling and tension control

Ending of film

Door open machine stop interlock

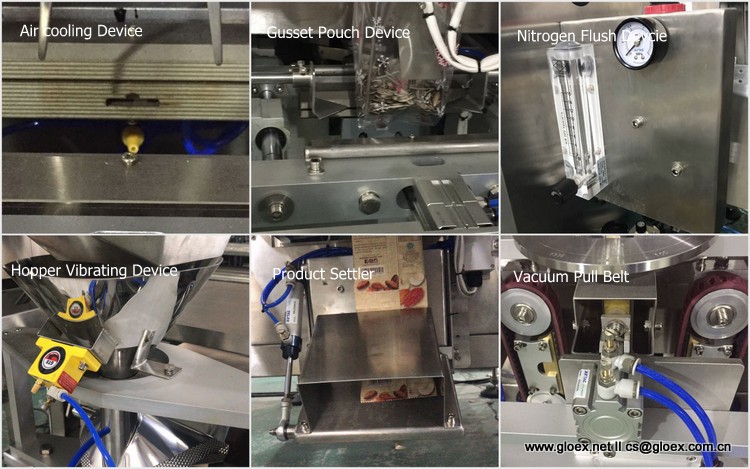

Optional Features

In order for adapting different requirements, the customized products can be supplied with the optional features as following

Stainless steel 316 product touching parts construction

Side gusset pouch form fill seal

Chain pouch cutting off

Euro slot or round hang hole punch

Pouch inflating or deflating, gas flush

Servo motorized horizontal sealing

Vacuum pull belts

Product settler

Tear notch

In-feed and take-away conveyors

Patterned plate or Teflon coating for the weighing plate

Integration with printers, metal detectors, and checkweighers

Practically, to form such a production line, most of the manufacturers separate the weigher and the vertical packaging machine. But this type machine, integrate the weigher and packaging unit in one machine, and has its advantages as indicated in the following table:

| Gloex Selected | Other Practice | Advantage |

Production line includes 1)Weigher & Packaging Integrated machine 2)1 Set of control system 3)1 Set of Z-shape materials loading device | Production Line includes 1)1 set of weigher 2)1 set of packaging machine 3)2 set of control system 4)1 Set of Z-shape materials loading device 5)1 Set of working platform | 1)No control interface, more stable operation 2)Smaller footprint 3)Lower Price |

| Catalogue/1T-xxxx | 1040-08 | 1440-05 | 1040-10 | 1250-10 | 1450-08 |

| HMI Dimension(inch) | 10.4 | 10.4 | 10.4 | 10.4 | 10.4 |

| Heads of Weigher | 10 | 14 | 10 | 12 | 14 |

| Bucket Volume(L) | 0.8 | 0.5 | 1.0 | 1.0 | 0.8 |

| Single Weighing Range(g) | 10-500 | 10-500 | 10-1000 | 10-1000 | 10-1000 |

| Max Weighing Range(g) | 1000 | 1000 | 1000 | 1000 | 1000 |

| Weighing Accuracy(g) | +/-0.3-1.5 | +/-0.3-1.5 | +/-0.3-1.5 | +/-0.3-1.5 | +/-0.3-1.5 |

| Max Film Width(mm) | 400 | 400 | 400 | 500 | 500 |

| Pouch Size-Length(mm) | 50-230 | 50-230 | 50-230 | 50-290 | 50-290 |

| Pouch Size-Width(mm) | 60-190 | 60-190 | 60-190 | 60-240 | 60-240 |

| Max Packing Speed (Pouches/min) | 60 | 90 | 60 | 90 | 90 |

| Power Consumption(kW) | 4.0 | 4.0 | 4.0 | 5.0 | 4.0 |

| Power Requirement(V/Hz) | 220V 50/60HZ | 220V 50/60HZ | 220V 50/60HZ | 220V 50/60HZ | 220V 50/60HZ |

| Vertical Sealing Method | Servo Motor | Servo Motor | Servo Motor | Servo Motor | Servo Motor |

| Horizontal Sealing Method | Pneumatic | Servo Motor | Pneumatic | Servo Motor | Servo Motor |

| Compress Air Requirement | 0.6 Mpa | 0.6 Mpa | 0.6 Mpa | 0.6 Mpa | 0.6 Mpa |

| Compress Air Consumption | 0.3m3/min | 0.2m3/min | 0.3m3/min | 0.3m3/min | 0.3m3/min |

| Approximate Net Weight(kg) | 500 | 540 | 550 | 650 | 650 |

| Packaging Dimension(mm) | 1556*1366*2078 | 1556*1366*2078 | 1530*1300*2300 | 1630*1320*2600 | 1630*1320*2600 |

This automatic vertical pouch packing machine,running at hundreds of proven projects, stable operation under excellent performance.follwing is the video link on our Youtube site

https://www.youtube.com/playlist?list=PLoI3FEOZ6j4P69WF-k7OgmF-cu0Y4y1bT

Please leave us message for more information