Product Code : PP113

TThese series machines are applicable for packing powder, small granule in form of bottle, can, or jar, configure with online weight checking and self-calibration, can lifting during filling. with different type of capping or sealing device is capable to form a production line

These series machines are applicable for packing powder, small granule in form of bottle, can, or jar, configure with online weight checking and self-calibration, can lifting during filling. with different type of capping or sealing device is capable to form a production line, the detail application description as following table:

| Issue | Application Description |

| Applicable Products | Suitable for powder or small granule dosing and filling. Such as sugar, salt, flour, starch, milk powder, coffee powder, dextrose, powder additive etc |

| Applicable Containers | Jar can, barrel or bottles. |

Following are the reference style of packaging

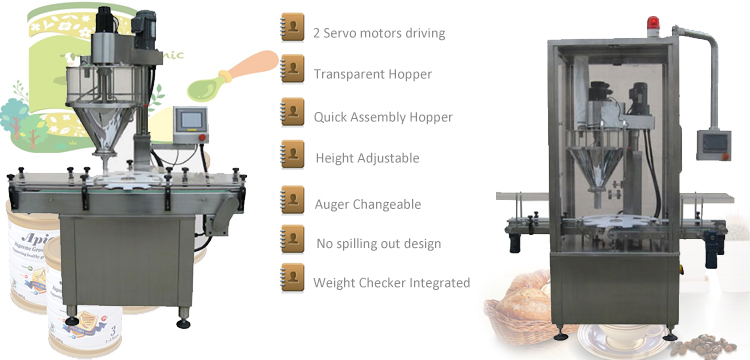

Standard Features

• Suitable for powder or small granule dosing and filling

• PLC &Touch screen HMI control enable easy operation parameter setting up and troubleshooting

• Configure with servo motors to drive dosing auger and the rotary plate, to achieve high dosing accuracy and speed.

• Pneumatic can/ jar lifting device, to assure no spilling out during filling process

• Weight checking device to assure each product be qualified, no weight checking requirement for downstream process

• Height adjustable devices, to adapt different height of the container

• Quick assembly hopper could be cleaned easily without tools

• Transparent hopper configuration, easy for operation monitoring

• Storing 10 groups of technical parameter for the different products, convenient for product changing

• By simply changing the auger parts, suitable for filling material from super fine powder to granule materials.

a) 2 Servo motors driving, more accurate dosing, faster speed

b) Transparent hopper, operation visible

c) Quick assembly hopper, easy for cleaning

d) Height adjustable to adapt different container

e) Auger changeable enable different product dosing and filling

f) Container lifting during filling, no spilling out

g) Weight checking integrated, investment saving

| Catalogue/1D-xxxxx | 2A-2 | 2B-2 |

| Container Dimension-‘mm | 1)Diameter 20-100 2)Height 15-150 | 1)Diameter 30-160 2)Height 50-260 |

| Filling Range ‘g | 1-500 | 10-5000 |

| Filling Accuracy | 1)<=100g,<=±2%; 2)100 - 500g,<=±1%; | 1)<=500g,<=±1%; 2)>500g,<=±0.5% |

| Filling Speed -cans/min | 20-50 | 20-40 |

| Hopper Volume-Liter | 35-Standard | 50-Standard 70-Extra Large |

| Power Requirement | AC208-415V 50/60Hz | AC208-415V 50/60Hz |

| Power Consumption-KW | 1.8 | 2.3 |

| Compress Air Required-Mpa | 0.6 | 0.6 |

| Compress Air Consumption-m3/min | 0.05 | 0.05 |

| Approximate Weight -kg | 250 | 350 |

| Dimension ( ‘mm ) | 1400*830*2080 | 1840*1070*2420 |

Following are the related video links on our Youtube site

Rotary type powder filling machine

If need more support , please contact us at: cs@gloex.com.cn