Product Code: PP114

This series of filling machines is capable of powder or small granule materials measuring and filling process, such as coffee powder, ground coffee, protein powder, medicinal powder, Herbal powder, food additives, starch, solid beverages, sugar, monosodium glutamate, flavors, spice., the detail application description as following table:

This series of filling machines is capable of powder or small granule materials measuring and filling process, such as coffee powder, ground coffee, protein powder, medicinal powder, Herbal powder, food additives, starch, solid beverages, sugar, monosodium glutamate, flavors, spice., the detail application description as following table:

| Issue | Application Description |

| Applicable Products | powder or small granule materials measuring and filling process, such as coffee powder, ground coffee, protein powder, medicinal powder, Herbal powder, food additives, starch, solid beverages, sugar, monosodium glutamate, flavors, spice |

| Applicable Containers | Various type of premade pouch, can, jar or bottle etc. |

Following are the reference style of packaging

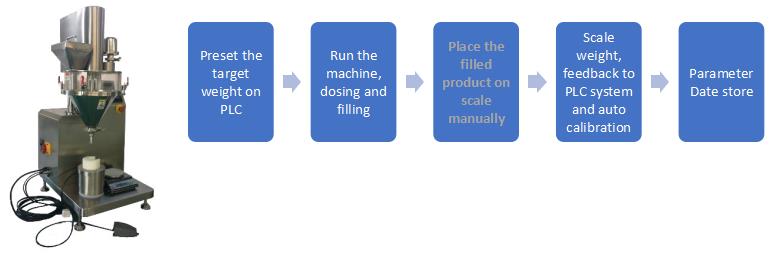

Weighing Feedback and auto calibration after filling

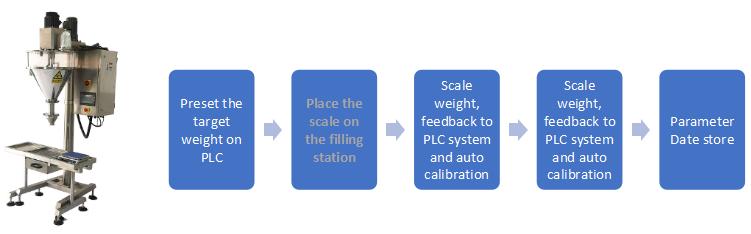

Real-time Weighing and auto calibration during filling

Standard Features

Apply for widely range of powder feeding, weighing, and filling.

Stainless Steel 304 construction for machine main body and products touching parts.

PLC &Touchscreen HMI control l Configure with servo motors to drive dosing auger, to achieve high dosing accuracy and speed.

Quick assembly hopper could be cleaned easily without tools.

Transparent hopper configuration, easy for operation monitoring.

Configured auto container taring feature.

Configured auto weight feedback program for weight self-checking and calibration to control the tolerance .

By simply changing the auger parts, suitable for filling material from super fine powder to granule materials.

Capable to store groups of technical parameters for the different products, convenient for product changing.

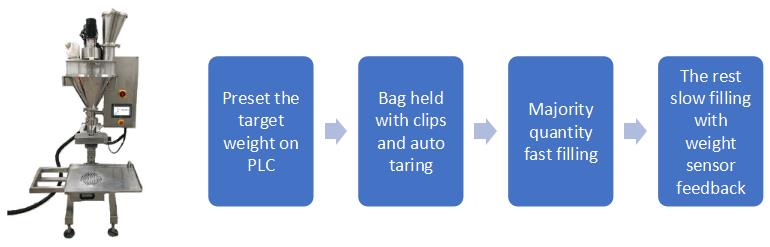

For bag clamping model, Pneumatic bag clamming design, release operators’ handsFor bag clamping model, configured weight sensor on the clamps, fast majority filling and slow filling for the rest, achieve high accuracy.

Optional Features

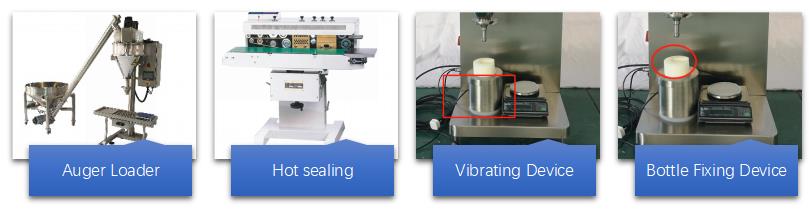

a) Powder loading device

b) Dust collecting device

c) Bag sealing or sewing device

d) Bottle vibrating device

e) Bottle fixing device

f) Other powder characteristic adaption accessories

| Type | ||||

| Filling Range(g) | 0.5-50 | 50-500 | 100-1000 | 1-5000 |

| Filling Accuracy | ≤±2-5%(subject to the characteristic of material) | ±1-5(subject to the characteristic of material) | ±1-5(subject to the characteristic of material) | ≤±3-5g subject to the characteristic of material) |

| Filling Speed (Times/min) | 10—60 | 10—20 | 5—20 | 3—5 |

| Tank Volume (L) | 10 | 26 | 50 | 50 |

| Power Supply | 220V 2P 50Hz | 380V 3P+N+E 50HZ | 380V 3P+N+E 50HZ | 380V 3P+N+E 50HZ |

| Power Consumption (KW) | 0.5 | 1.1 | 1.5 | 1.7 |

| Approximate Weight (KG) | 70 | 200 | 260 | 260 |

| Dimension (mm) | 630×570×1000 | 800×700×1900 | 800×1200×2250 | 800×1200×2450 |

Following is the link of video playlist on our Youtube site

Semi automatic powder filling machine +5g powder bottle filling with PLC display

If need more information , please contact us at: cs@gloex.com.cn