Product Code: PP116

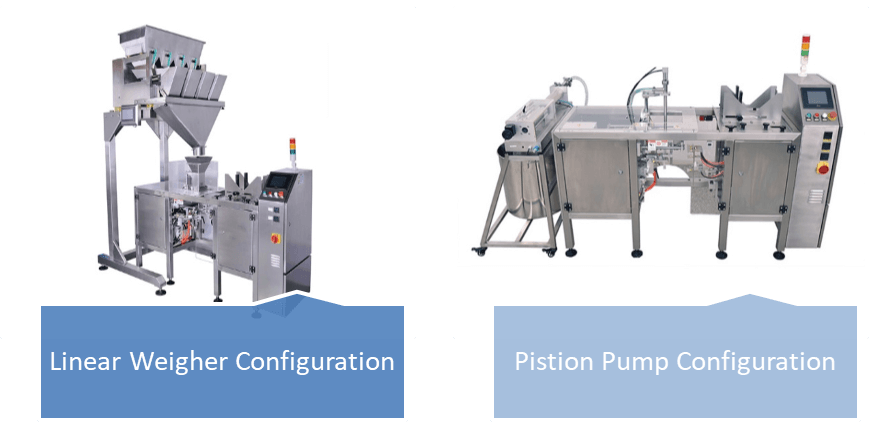

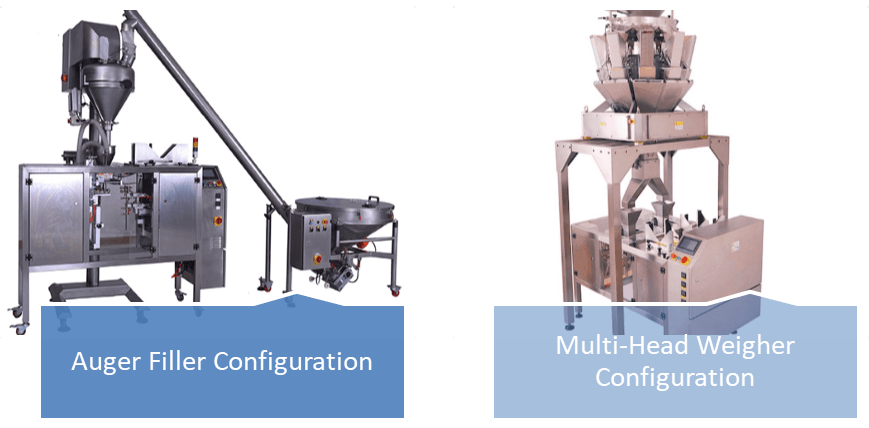

This machine is applicable for, subject to configure with different dosing device, filling with powder, granule or liquid into a premade pouch and sealing, the detail application description as following table:

This machine is applicable for, subject to configure with different dosing device, filling with powder, granule or liquid into a premade pouch and sealing, the detail application description as following table:

This machine is applicable for, subject to configure with different dosing device, filling with powder, granule or liquid into a premade pouch and sealing, the detail application description as following table:

| Issue | Application Description |

| Applicable Pouches | By configuring of different accessories, apply for Laminate heat sealable pre-made pouches like flat pouch, gusset pouch, stand up pouch, quad sealed pouch, or stand up pouch with zipper etc. |

| Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder granule, or other irregular solidity materials. |

| Applicable Packaging Material | Laminate Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL/PE etc. |

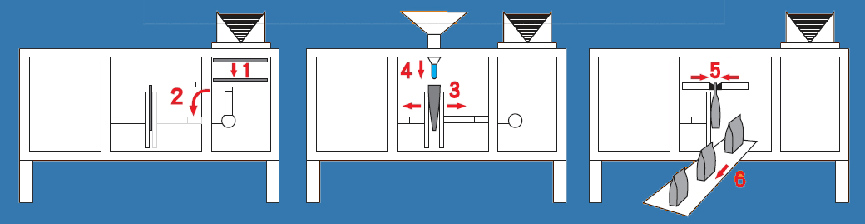

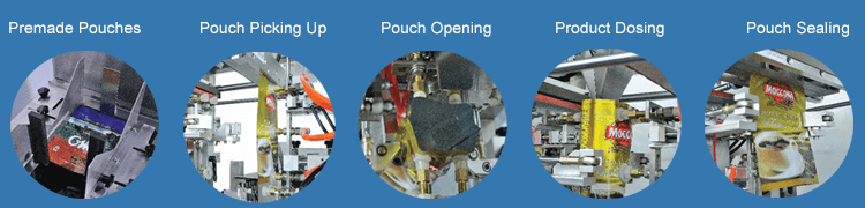

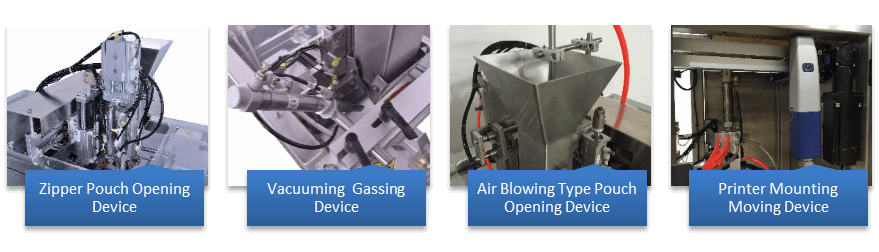

The working processes include: pouch pick up, pouch open, dose, fill and seal. By configuring with different accessories, like zipper opening device, vacuuming and gassing device, capable to fill with different type of pouch, or achieve different process requirement. following are the typical working process diagram:

Standard Features

•Non-zipper pre-closed type flat or stand up pouch fill and seal

•Durable stainless steel 304 construction for frame and surface

•Stainless steel 304 for product touching parts

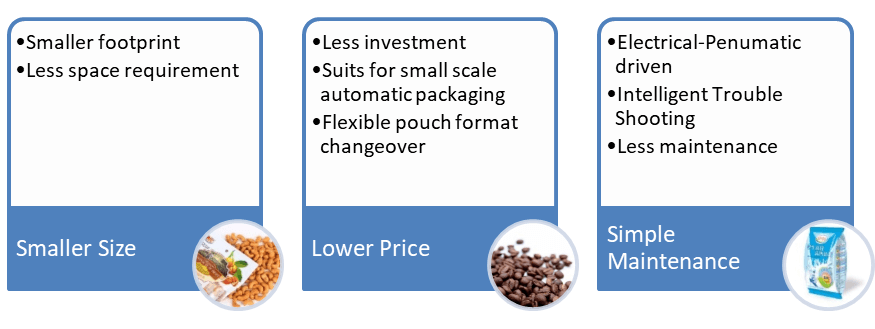

•Electrical and pneumatic driven, simple operation and maintenance

•Program Logic Controller and touch screen HMI Control

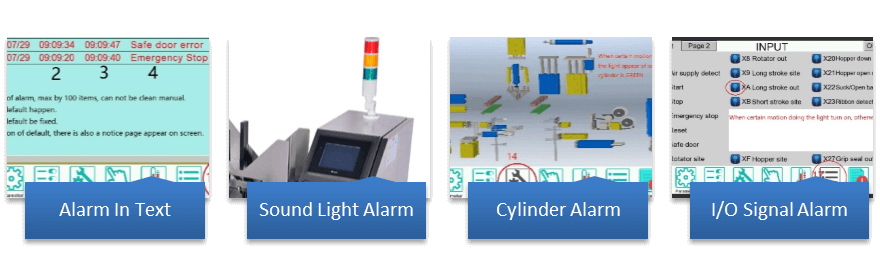

•Complete trouble shooting program with sound and light alarm

•Simple and quick pouch format changeover

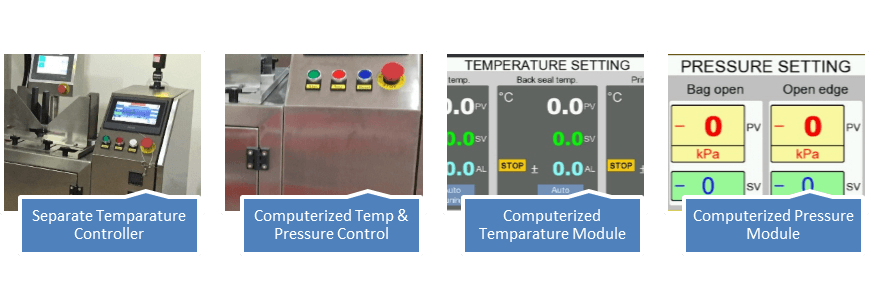

•Separate Temperature Controller configuration, ensure reliable sealing quality

•No bag no fill and seal

•Pouch not open completely, no fill and seal

•Door open machine stop interlock

Optional Features

1)Different dosing devices for various products

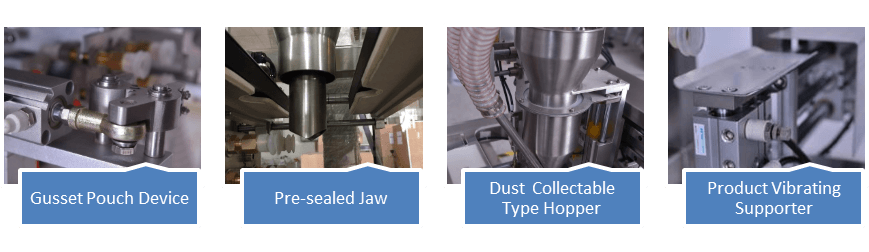

2)Zipper opening device or gusset pouch device

3)Special pouch magazine

4)Coding devices, like emboss, hot stamp

5)Quality control devices, like checkweigher, metal detector, X-ray inspection

6)Dust collectable type hopper and/or dust collector

7)Pouch vibrating supporter for heavy fills or for loose product

8)Inkjet or Laser printer mounting and moving device

9)Vacuuming and pre-sealed jaw devices

10)Vacuuming, gassing and pre-sealed jaw devices

11)Air blowing type pouch opening device

12)Air exhausting device

13)Computerized vacuum, temperature control module by PLC

14)Vacuum pump

15)Incline, bucket or other types infeed, exit conveyor

Note:

1)the zipper opening device and gusset pouch device can’t be mounted on the same machine

2)Vacuuming and/or gassing device shall be mounted with pre-sealed jaw

3)The ribbon coding device applies the pouch width >=120mm only

| Catalogue/1R-xxxxx | 200 | 300 | 430 |

| Work Stations | 1 | 1 | 1 |

| Pouch Size-Length(mm) | 100-200 | 100-300 | 100-430 |

| Pouch Size-Width(mm) | 70-150 | 80-300 | 80-300 |

| Packing Speed (pouches/min) | 0-26 | 0-15 | 0-15 |

| Reference Filling Range(g/pouch) | 5-200 | 5-1500 | 5-2500 |

| Power Requirement | AC220V 50/60HZ | AC220V 50/60HZ | AC220V 50/60HZ |

| Power Consumption(kW) | 1.0 | 1.2 | 1.4 |

| Compress Air Required (Mpa) | 0.65 | 0.65 | 0.65 |

Compress Air Consumption(m3/min | 0.25 | 0.35 | 0.45 |

| Dimension(mm) | 1078*535*1060 | 1750*510*1250 | 1750*510*1350 |

| Catalogue/1R-xxxxx | Duplex | Twins | Pickup |

| Work Stations | 2 | 2 | 1 |

| Pouch Size-Length(mm) | 100-300 | 100-300 | 250-500 |

| Pouch Size-Width(mm) | 80-200 | 80-300 | 380-600 |

| Packing Speed (pouches/min) | 0-30 | 0-30 | 0-10 |

| Reference Filling Range(g/pouch) | 5-1000 | 5-1500 | 2000-5000 |

| Power Requirement | AC220V 50/60HZ | AC220V 50/60HZ | AC220V 50/60HZ |

| Power Consumption(kW) | 1.5 | 2.0 | 2.0 |

| Compress Air Required (Mpa) | 0.65 | 0.65 | 0.65 |

Compress Air Consumption(m3/min) | 0.45 | 0.65 | 0.4 |

| Dimension(mm) | 1800*1050*1380 | 1078*1120*1400 | 1750*510*1300 |

Note:

1)Type 200, Type Duplex, Type Pickup apply for flat pouch, stand up pouch only, the other types are upgradable for zipper, gusset or qual sealed pouch subject to configure with necessary accessories

2)Production speed may vary depending on product characteristics, pouch conditions, operator skills and ambient filling conditions

3)For side gusset pouch without pre-welded gusset, in order to ensure the re-gusseting process, from the top edge to the level of fill shall >=110-140mm, which depend on the characteristic of the packaging material

4)The size of pouch shall meet the following requirements if apply for zipper pouch:

a)The width >=130mm

b)The Length >=160mm

c)The distance from the top edge to the zipper >=30mm

Following is the video playlist on our Youtube site

Linear Type Premade Pouch Packaging Machine

For more information or technical support, please contact us at : cs@gloex.com.cn