Beef And Sauce Tin Can Filling Seaming Machine

Project Information

1) Project Code: CSC905

2) Project Location: Germany

3) Product: Beef +sauce

4) Packaging Type: Tin can

System Overview

3 sets of Can Seamers

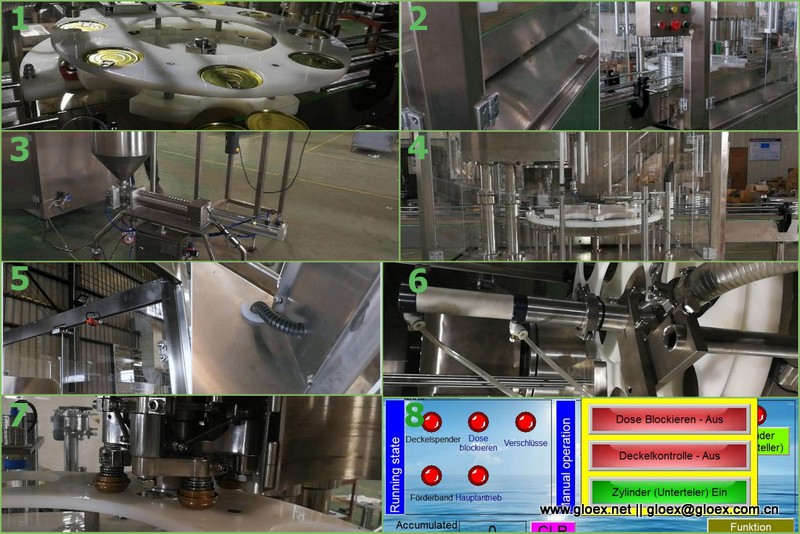

The following photo indicates that 2 sets of automatic can seamer and 1 sets of semi-automatic can seam are ready

Remark: configure with safety shield and operation table

Automatic 8 station can seamer

Machine Details

1) Double rotating star to ensure accurate lid positioning

2) Integrated with filling nozzle which connect to liquid filling machine

3) Drainage groove to collect the liquid may spilling out

4) Conveyor mounted on top of the control box to minimize the liquid leak into

5) Protection shield with “ door open and machine stop “ interlock

6) Titanium coating seaming rollers enable long life cycle and reliable seaming quality

7) Integrated filler to achieve filling and seaming in one machine

8) Configure with Chinese , English and German Language

Related Video

Following is the related video link on our Youtube site

Testing Video for Semi-automatic Can Seamer

1) Diameter 99mm tin can

2) Diameter 83mm can

Empty Can Infeed Turntab

1) Feeding Turntable

Testing Video for 99mm can

1)Test Video for 99mm diameter tin can with water filling process

2)99mm diameter tin can seaming quality check

3)99mm diameter tin can water filling and seaming, 1200gram water, run at 12 cans per minute. , intermittent running of seaming heads

4)99mm diameter tin can water filling and seaming, 400 gram water, run at 22 cans per minute. Continuous running of seaming heads

5)Seaming cross-section check of 99mm diameter can

6)Seaming dimension comparison of seamed end

Testing Video for 153mm can

1)Test Video for 153mm diameter tin can with water filling process

2)Seaming cross-section check of 153mm diameter can

3)153mm diameter tin can seaming aspect check

Testing Video for 75mm can

1)75mm can seaming process demonstration

2)75mm can seaming aspect check

Can Size Changing Procedure

1)First star installation

2)Seaming Head Height Adjustment and Fixing

3)Seaming Head Height Adjustment and Fixing

4)Second star installation

5)Rotating stars height adjustment

6)Lidding Device Installation& Seaming Head Height Adjustment

For more technical support,please contact us at cs@gloex.com.cn

Weighing and Packaging Integrated Vertical Form Fill Seal Machine

Weighing and Packaging Integrated Vertical Form Fill Seal Machine High Speed Rotary Type Automatic Round Shaped Can Seaming Machine

High Speed Rotary Type Automatic Round Shaped Can Seaming Machine Linear Type Premade Pouch Packaging Machine

Linear Type Premade Pouch Packaging Machine Horizontal Type Premade Pouch Packaging Machine

Horizontal Type Premade Pouch Packaging Machine Rotary Type Automatic Powder Double Filling & Weighing Machine

Rotary Type Automatic Powder Double Filling & Weighing Machine Rotary Pre-made Pouch Packing Machine

Rotary Pre-made Pouch Packing Machine